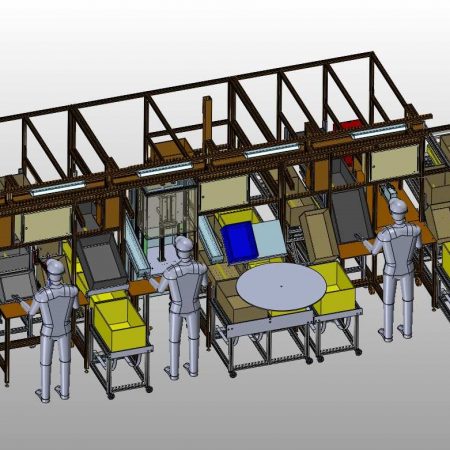

JAFS specializes in assembly and mounting lines

A line is composed of a set of specialized workstations and arranged in a pre-established order corresponding to the succession of the assembly operations of the components of a product.

An ergonomic study is realised for each workstations.

The number of operator stations is linked to the assembly range of the product.

An assembly line is characterized by the employment of an operator and the management of the cadence in order to optimize its productivity, its traceability.

It is possible to integrate robots.